- GST No. 22AUEPS1008G1Z4

- Send SMS

- Send Email

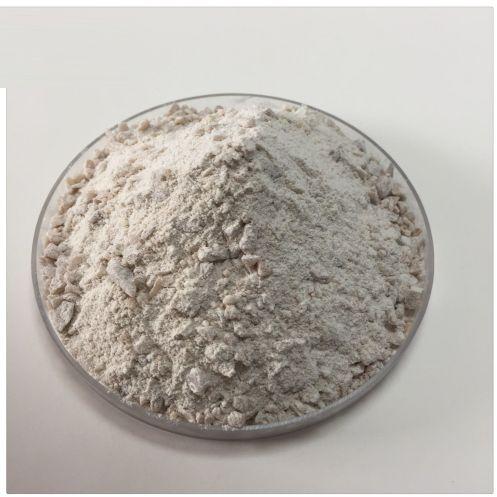

Ramming Mass

Kirti Mineral Works is well known and trusted Ramming Mass Manufacturer in India. Silica ramming mass is also known as acidic ramming mass. The raw material of silica ramming mass is high-quality quartz, mixed with high-quality boric acid. In Silica content, we get ninety-nine per cent of raw material. Usually, we add one to one and a half per cent to premix with quartz, but it can be changed depending on the requirements of the customers. The Silica ramming mass of our company is one of the most popular products of our company.

It plays a very crucial role in the induction furnaces during the steel melting process. In line induction furnace this substance is used to make the quality smooth and work better. It provides a more efficient output from the furnace.

Benefits Of Silica Ramming Mass

• It has an extremely high bonding strength

• The Silica ramming mass has a high erosion resistance

• You get guaranteed service life with free engineering services

• It does not expand or shrink with the temperature changes

The Benefits of these products is what makes them popular among people all around the world. These have amazing features and characteristics that make it the number one choice for several purposes.

To know more about our services and products you should call and speak to our executives in no time. Order our products in your required amount and get them delivered to your doorstep on time.

| Business Type | Manufacturer, Supplier |

| Type | Ramming Mass |

| Shelf Life | Standard |

| Color | Natural |

| Packaging Type | As per buyer's requirement |

| Moisture | 0-5% |

| Country of Origin | India |

| Business Type | Manufacturer, Supplier |

| Type | Premix Ramming Mass |

| Shelf Life | Standard |

| Color | Natural |

| Packaging Type | As per buyer's requirement |

| Moisture | 0-5% |

| Country of Origin | India |

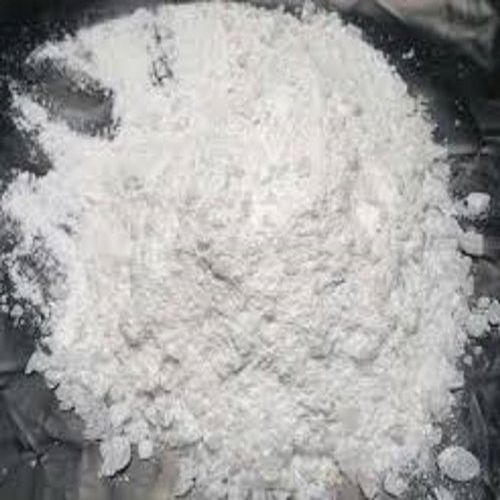

Are you looking for Premix Acidic Ramming Mass Suppliers in India? You are certainly in the right place. Our company Kirti Mineral Works have been serving our respected clients by manufacturing and supplying excellent quality Acidic Premix Ramming Mass.

For its enhanced quality, our dexterous professional's process this chemical with utter care and precision using top-notch quality chemical compounds in sync with set industry norms. This product is a colourless solid and easily soluble in water. Smooth working of furnaces, better output and metallurgical control requires better quality of lining. So, this, premix provides that smooth lining to all equipment and machines. Acidic Premix Ramming Mass can be availed from us in different packaging quantities as per requirements and that too at reasonable rates.

Salient Features :

• Perfect and even composition.

• Free from contaminants and impurities.

• Excellent and reliable performance.

• Cost-effectiveness.

Why Choose Us?

We are the best Premix Acidic Ramming Mass Manufacturer in the country today. We have been in this field for years and have gained huge popularity in the market today. The products of our company are made under the supervision of experts and professionals and are tested after every stage. We make sure that our customers meet the expectations of our customers and clients and are of international standard quality.

Choose us and get our services today. For more details and information contact us and speak to our executives without any hesitation.

| Business Type | Manufacturer, Supplier |

| Type | Silica Ramming Mass |

| Shelf Life | Standard |

| Color | Natural |

| Packaging Type | As Per Buyer's Requirement |

| Country of Origin | India |

| Moisture | 0-5% |

Your search for Silica Ramming Mass Manufacturers India is over with us. Our company Kirti Mineral Works is popular and successful in the market today. We have Silica ramming mass, also known as acidic ramming mass or quartzite powder or quartz powder. Silica ramming mass is a product to be used in Coreless Induction Furnaces for melting of scrap to liquid steel. It is a dry lining refractory that can be used for all types of iron, steel, aluminium and foundries.

The raw material of silica ramming mass is high-quality quartz, mixed with high-quality boric acid. The silica content of its raw material is more than 99%. Generally, we will add 1 % to 1.5 % to premix with quartz, but it can be changed as per customers’ requirements. This is one of the most popular products in our company, according to customers’ feedback, this product can be used for 20 heats to 40 heats on furnace capacity from 10MT to 40MT.

Advantages:

• High erosion resistance

• High bonding strength

• Short lead time

• Free engineering services to guarantee service life.

Choose to deal with us and get our services today. Speak to our executives if you have any questions or queries about our services. We take orders in bulk and deliver them to our customers always on time. Contact us and order our products today. We are the best Premix Silica Ramming Mass Suppliers.

| Business Type | Manufacturer, Supplier |

| Type | Ramming Mass, Acidic Ramming Mass |

| Shelf Life | Standard |

| Color | Snow White, Natura; |

| Packaging Type | BOPP Bags, As Per Buyer's Requirement |

| Moisture | 0.00 |

| Packaging Size | 50 Kg |

| Country of Origin | India |

| Business Type | Supplier, Retailer |

| Al2O3 Content | 0.5% |

| SiC Content (%) | 98.5% |

| CaO Content (%) | 0.01 |

| MgO Content (%) | 0.8-1.2% |

| CaO Content | 0.3% |

| CrO Content | 0.1~0.3% |

| SiO2 Content | >99% |

Kirti Mineral Works has the necessary technical expertise as well as a large production facility in Raigarh, Chhattisgarh. Experienced personnel with a thorough understanding of refractory materials combine different grain sizes of silica in precisely the proper quantities to create silica ramming mass for ladle lining suited for a variety of induction furnaces.

The ability to endure readily absorbing thermal shocks is a crucial feature of ramming mass. It also does not fracture as a result of numerous power outages during induction furnace operation. We produce high-quality silica ramming mass with a high density of silica quartz. This is why it is a well-known brand among silica ramming mass goods made in India.

Our Ladle Ramming Mass can withstand extremely high temperatures. It can function at full capacity. It offers great lining performance as well as good heat conductivity. It is capable of withstanding the strains imposed by heat cycles while in use. This is also notable for its good volume stability, little apparent porosity, and improved heat stability of the structure.

At very high temperatures, Ladle Ramming Mass is likely to be employed. It may be used to make a variety of refractory materials. When opposed to other refractories, it also has reduced heat losses. For coreless electric arc furnaces, Ladle Ramming Mass can be utilized.